Case Studies

Contract Production

Moulded fibre glass horse float roofs.

Pit box for underground cables

Industrial Fabrication

Floats for sewerage treatment works

Various fittings for large pipe applications

Reducing Cone Desalination plant

Gate Valve Housing Desalination plant

Secondary Fit-out services

Fibre Composites are able to not only produce solutions for their clients but are able to provide secondary fit-out services for those solutions.

When several sections of a product need to be fibre glassed together, have holes drilled, need plumbing or have fittings supplied and installed Fibre Composites can provide the solution.

Contact Us

Fibre Composites International Pty LtdUnit 1 / 18 Francis Road

Wingfield South Australia 5013

Phone: 08 8345 2299

Fax: 08 8345 0481

International

Phone: International 61 8 8345 0481

Fax: International +61 8 8345 0481

E-Mail: info@fibrecomposites.com.au

Contract Production

Contract Production

Production techniques employed here at Fibre Composites enable our staff to manufacture a wide and varied range of components for a number of clients whose products cover an immense variety of industries.

Anywhere from mining, electrical, transportation, aqua culture or consumer goods the list of products that contain something produced here at Fibre Composites continues to grow with many satisfied customers both here in Australia and overseas.

Our staff can produce composite moulded products from design through to completion. With patternmakers, mould fabricators and production experts on hand, your new product can be skilfully under way without the delay of outsourcing these specialist skills.

Continuous production is a specialty at Fibre Composites where our up to date facility can handle small to large production runs.

One call to our team will get your project off to a great start - our contact details are

Fibre Composites

Fibre Composites International Pty Ltd

Unit 1 / 18 Francis Road

Wingfield South Australia 5013

Phone: 08 8345 2299

International 61 8 8345 0481

Fax: 08 8345 0481

Fax: - International +61 8 8345 0481

E-Mail:

info@fibrecomposites.com.au

Contract production case studies

;

;

Portable ensuite fills the need for temporary bathroom alternatives in the building renovation and social functions market.

The fibreglass inner and outer shells are made by Fibre Composites while the plumbing and electrical work are carried out by Add-A-Bathroom The complete unit is delivered to the client ready to use.

These units are widely available

throughout

Click here for more information on Add-A-Bathroom website

Fully moulded fibre glass horse float roofs.

Our client builds horse floats for distribution around Australia. At Fibre Composites we produce several different size fully moulded fibre glass roofs to suit our client's model range.

The series of photos above show a completed fully moulded fibre glass roof at our facility, the roof being fitted to a horse float in our client's factory and finally the completed float, assembled and ready for delivery.

Click here for more information on the Olympic website

Our client manufactures and supplies products for the fitness market. In this case we produce among other products a fully moulded fibre glass instrument panel for one of their machines.

Our pictures show the completed instrument panel and the panel mounted to the machine with the instruments fitted.

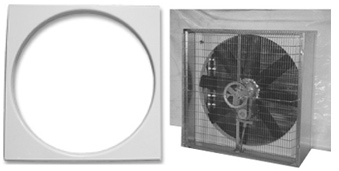

Our client manufacturers large industrial fans for industry. At Fibre Composites we produce the fan mount for these fans. The fan mount is approx 1.8 metres in diameter. Our pictures shows the finished mount [left] and our client's fan with the surrounding shroud.

Our client distributes pumps for various applications. In need of a lightweight yet strong base that was impervious to rust and chemicals they asked Fibre Composites to provide a solution. We now produce a range of fully moulded fibre glass bases and stands for our client's products.

Pit Box for underground cables.

Our client lays underground cables and required a solution that enabled the cables to be accessed for inspection or repair. The solution needed to be strong, made from material that would not degrade and light enough for our client's technicians to install on site.

Fibre Composites provided a solution produced from Fibre Glass that is designed to be much stronger than the plastic alternative and much lighter to handle than concrete boxes but still gives the strength required.

Pictured below is a pit box being installed on site ready for the cable layers.

An automotive battery manufacturer needed a solution to stack batteries on pallets for storage and ready for movement by fork lift around their warehouse.

The batteries contained acid, a corrosive substance and were stored in a fully charged state. The solution also needed to be strong yet light enough to place in position by one person.

Fibre Composites provided a solution produced from fibre glass which is not affected by the acid does not conduct electricity and is strong yet lightweight compared to steel or timber.

One call to our team will get your project off to a great start - our contact details are

Fibre Composites

Fibre Composites International Pty Ltd

Unit 1 / 18 Francis Road

Wingfield South Australia 5013

Phone: 08 8345 2299

International 61 8 8345 0481

Fax: 08 8345 0481

International +61 8 8345 0481

E-Mail:

info@fibrecomposites.com.au